The role of collaborative robots is rapidly evolving. Once used mainly for light-duty assistance, cobots today are transitioning into high-performance automation tools capable of industrial-grade speed, accuracy, and cycle stability. As production environments shift toward higher mix, fluctuating demand, and tighter labor availability, cobots are becoming a core strategic element in modern factories—not peripheral, but foundational.

This transition is driven by converging pressures:

Greater payload expectations, faster takt time, tighter precision requirements, smarter safety, and easier deployment across scenarios.

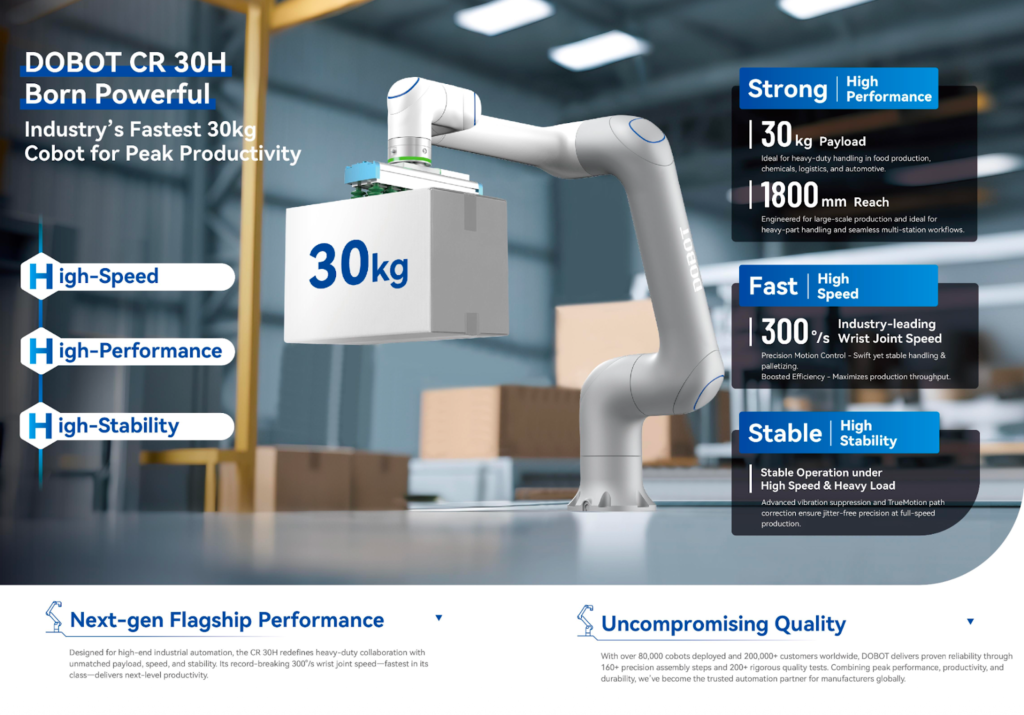

Speed, Payload, and Stability Are No Longer Trade-offs

New high-payload cobots have shown that speed and safety can coexist.

Systems in the 30kg class now deliver:

- 300°/s wrist joint speed

- ±0.05 mm repeatability

- 1800 mm reach

These capabilities unlock high-throughput palletizing, multi-station handling, and precision machine-tending roles that once belonged solely to traditional industrial robots.

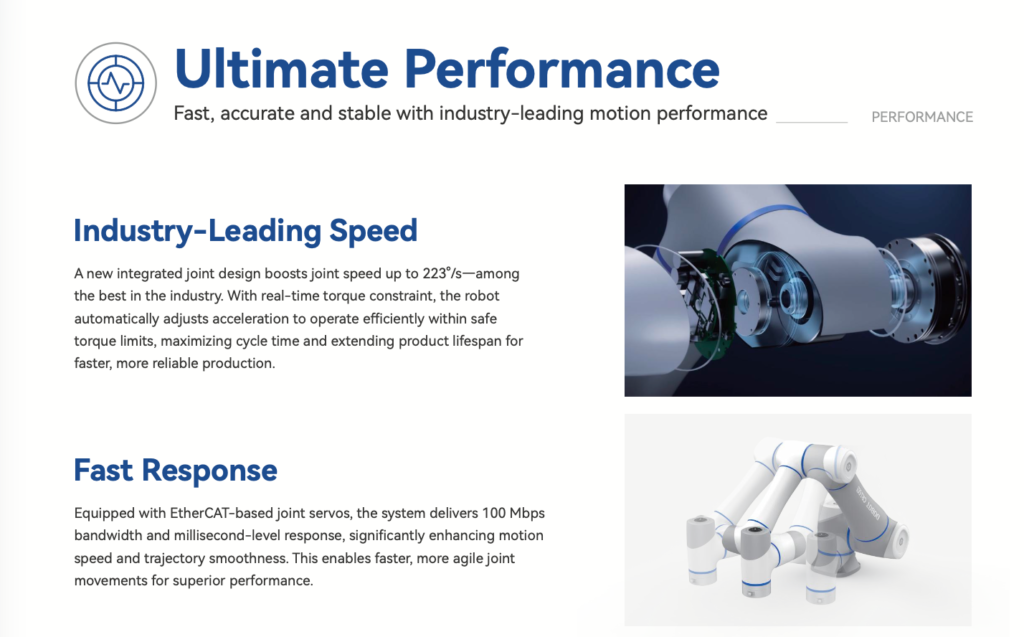

Mid-range collaborative robots—those optimized for general automation—are also seeing major motion improvements, with ±0.02–0.03 mm repeatability, 223°/s joint movement, and real-time torque constraint for smooth, stable motion even under varying loads.

The performance gap between cobots and industrial robots is narrowing, while cobots retain the flexibility that makes them operationally appealing.

Motion Performance Has Become a Competitive Differentiator

Motion quality—how a robot accelerates, holds position, absorbs vibration, or handles small trajectory deviations—directly impacts production quality, assembly accuracy, and consistency.

Recent innovations include:

- High-density servo drives with millisecond response

- Vibration suppression algorithms keeping endpoint jitter <0.4 mm

- Laser-calibrated precision for sub-millimeter tasks

- Electromagnetic braking that locks joints within milliseconds

These improvements enable cobots to take on tasks like dynamic dispensing, small-component assembly, and high-accuracy gluing that previously required specialized equipment.

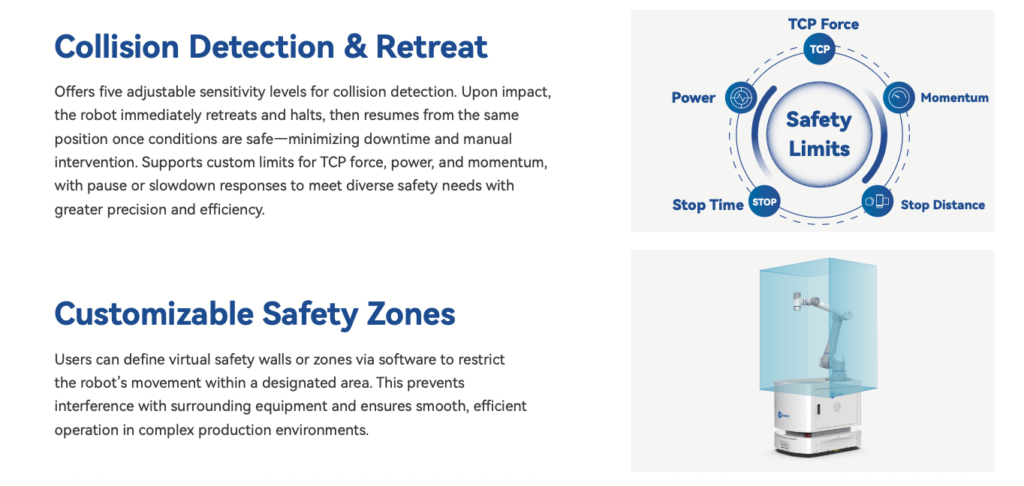

Safety Is Becoming Smarter—Not Slower

Older generations of collaborative safety relied on one principle: “slow down when humans are near.”

Modern cobots use intelligent, predictive safety layers:

- 360° proximity sensing

- non-contact collision prediction

- multi-zone virtual safety walls

- faster brake response

This allows cobots to maintain higher speeds without compromising safety, which is critical in workflows where humans and robots frequently interact—such as packaging, electronics assembly, mobile inspection, and lab automation.

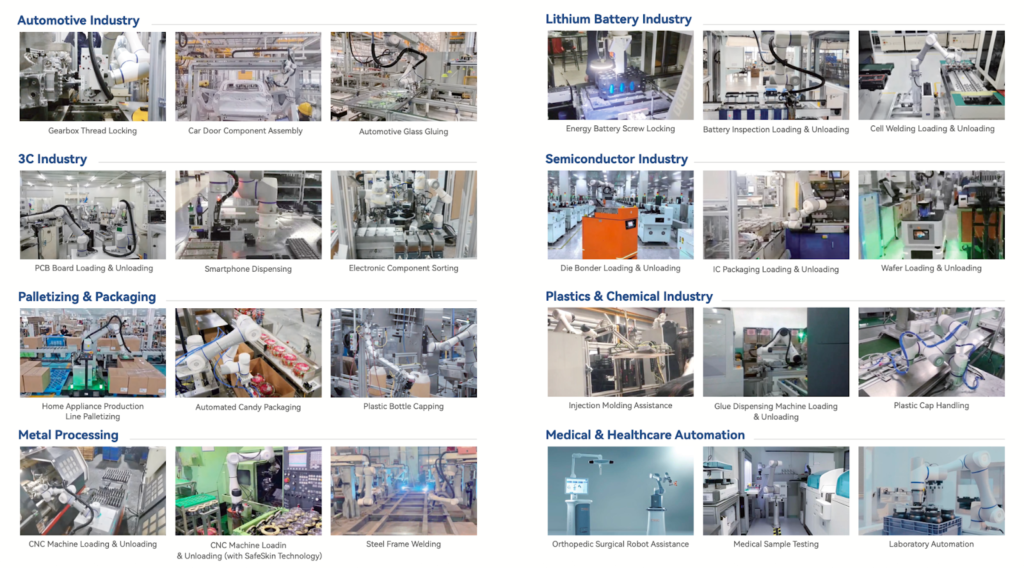

Cobots Are Becoming Full-Scenario Automation Platforms

Today’s cobots operate across nearly every industrial vertical, supported by richer ecosystems of software, sensors, grippers, and process packages:

- food & beverage

- metal processing

- automotive sub-assembly

- semiconductor handling

- 3C electronics

- laboratory and medical automation

Dedicated packages for welding, palletizing, CNC loading, dispensing, and inspection greatly reduce setup time and make cobots easier to scale across new production lines.

The Joint Level Is Becoming the Heart of Innovation

As cobots grow more capable, the importance of joint-level performance grows with them.

Next-generation automation requires joints that combine:

- high torque density

- smooth, low-vibration rotation

- thermal efficiency for long duty cycles

- encoder precision

- compact mechanical integration

- stable control under dynamic load

This is where ongoing advancements in motor architecture, servo control, harmonic integration, and force sensing will shape how far collaborative robots can evolve.

Collaborative robots have moved beyond being “safe robotic helpers.”

They now represent a high-performance automation category, delivering industrial-grade motion with intuitive deployment. As industries demand faster cycles, safer interaction, and more adaptable automation, the future of cobot performance will be defined at the joint level—where precision motion, intelligent control, and mechanical design come together.

As these technologies continue to advance, we are excited to bring this new generation of collaborative robot solutions to the North American market. Our goal is to support manufacturers, integrators, and research teams with motion platforms that deliver reliability, precision, and long-term scalability. We look forward to working closely with partners across the region as high-performance cobots become an increasingly integral part of modern automation.