Automation is entering a new phase. Across manufacturing, logistics, medical devices, laboratory automation, and emerging service robotics, systems are becoming smaller, faster, and increasingly software-defined. The industry’s focus has shifted from simply “automating tasks” to building machines that can collaborate, adapt, and operate continuously with minimal downtime.

Several global trends are driving this shift:

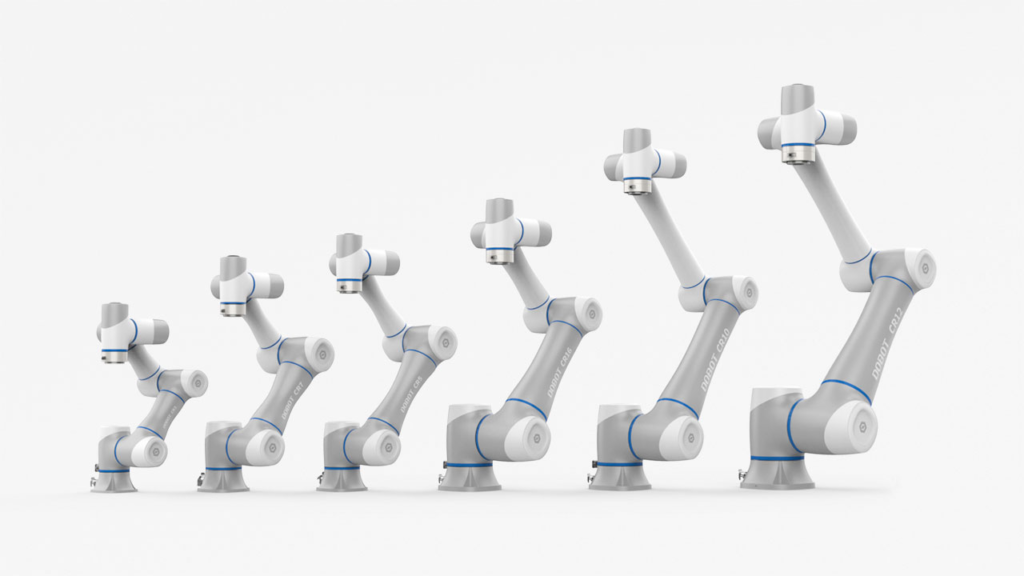

1. The rise of lightweight and modular robotics

From collaborative robots to mobile manipulators, more designs emphasize compact form factors, simplified mechanical structures, and flexible deployment. This requires actuators and motor systems that deliver high torque without adding bulk.

2. Greater precision in repetitive and high-mix operations

Electronics assembly, optical inspection, packaging, and medical automation all demand smoother motion, lower vibration, and tighter positional accuracy. Traditional servo motor packages often create limitations in size, inertia, or integration flexibility.

3. The push for energy-efficient and thermally-stable systems

As robots operate longer hours and in smaller enclosures, motors must maintain performance while improving thermal behavior and reducing noise and power consumption.

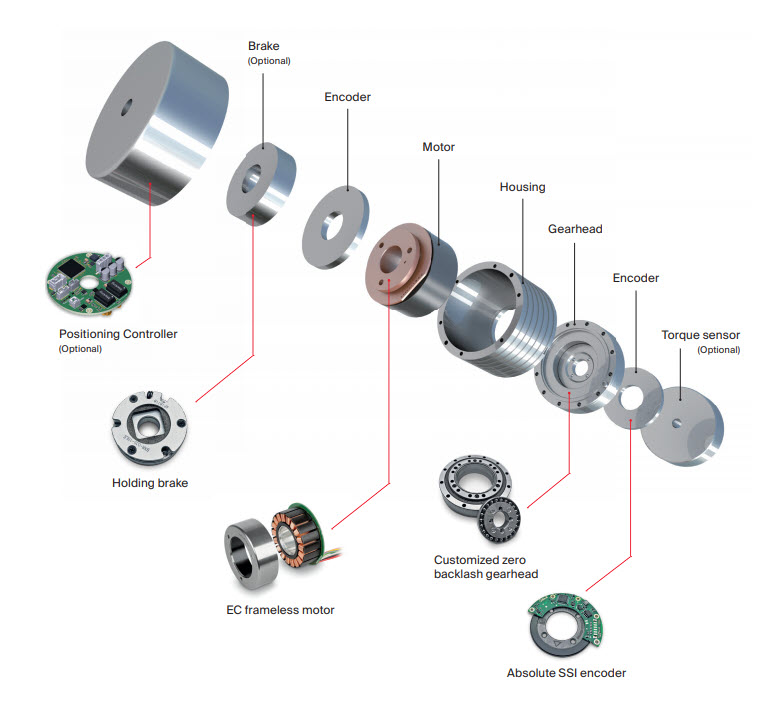

Why frameless torque motors are becoming a core building block

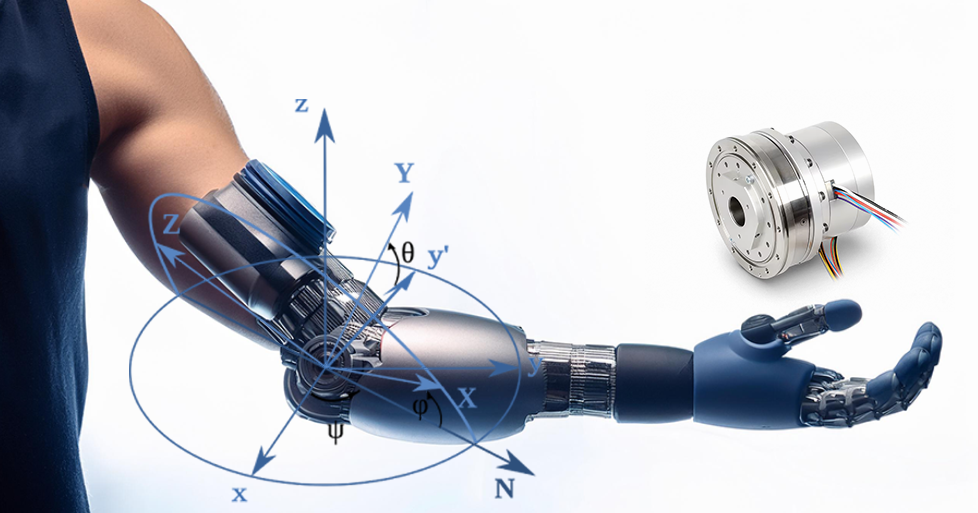

As robotic systems evolve, frameless torque motors — once used mainly in high-end industrial platforms — are now becoming standard in:

- joint modules for collaborative arms

- compact rotary actuators

- precision grippers and end-effectors

- camera gimbals and stabilization systems

- inspection and measurement platforms

- AMR lifting modules and drive units

Their growing adoption comes from several fundamental advantages:

• High torque density in a compact footprint

Because frameless motors integrate directly into the mechanical structure, they eliminate the housing and allow designers to dedicate more space to gearing, sensors, or custom actuators.

• Smooth, low-cogging motion

This is essential for collaborative robots, precision assembly, and force-controlled applications.

• Superior thermal management

Direct integration with the joint structure enables better heat dissipation, supporting longer duty cycles.

• Mechanical design freedom

Engineers can customize the rotor/stator interface to match unique requirements—something difficult with off-the-shelf servo motors.

• Lower inertia and improved backdrivability

Critical for human-robot interaction, safety-rated motion, and compliant control.

How companies are applying these advantages

Modern robotics companies increasingly design their own joint modules or custom actuators instead of relying on generic servo packages. This lets them achieve:

- lighter multi-axis arms

- quieter operation

- higher stiffness under load

- lower overall system cost at scale

- tighter integration of encoders, brakes, and harmonic reducers

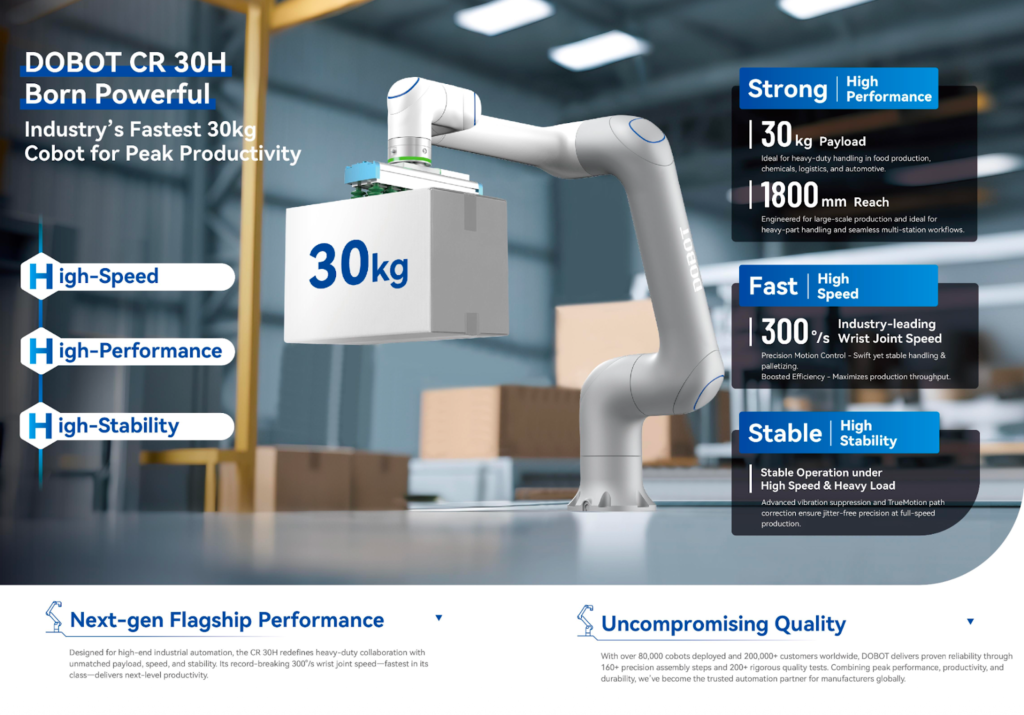

This shift is visible across the industry,from high-precision cobots to specialized automation modules and inspection systems—where motion performance directly determines product competitiveness.

Where our work naturally fits into this evolution

As more companies adopt frameless motor architectures, engineering teams often require support in tuning torque curves, adapting mounting structures, selecting encoder/brake configurations, or scaling from prototype to production.

Our role is simple:

work with robotics and automation teams to provide the motor foundation that enables these next-generation designs.

Not by pushing catalog parts, but by helping them build the exact joint behavior their system needs—whether that’s stiffness, smoothness, torque density, backdrivability, or thermal performance.