Compact Power |

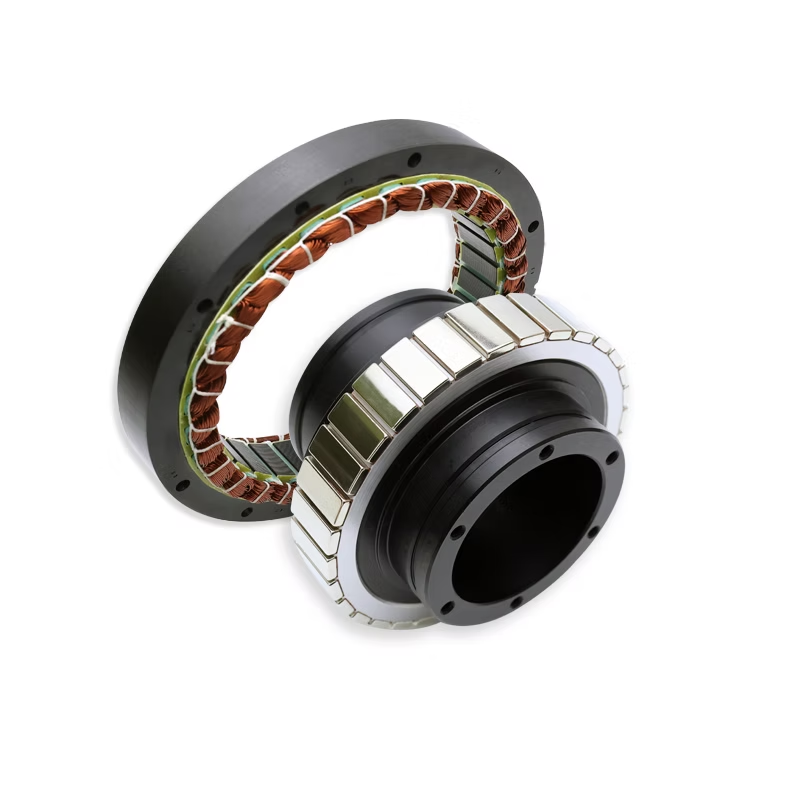

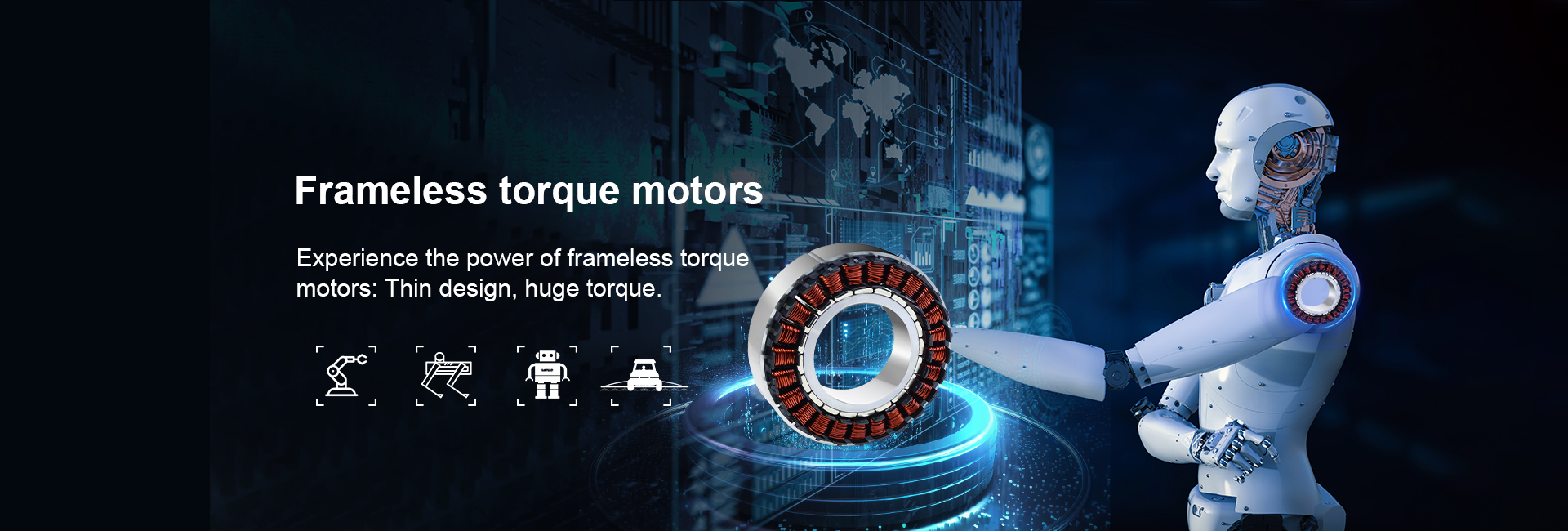

Frameless Torque Motors for Robotic & Automation Systems

Precision motion. Limitless integration for your next-generation robotic joints.

Designed for seamless integration into high-end equipment, the Frameless Torque Motor Series from Maintex IntelliCore delivers direct-drive performance with high torque density, low inertia, and precise control. These motors excel in compact systems requiring smooth, accurate motion, making them ideal for robotics, automation, medical devices, AI-driven platforms, and advanced industrial machinery.

Intelligent Motion |

High-Torque Direct-Drive Solutions for Modern Motion Systems

Maintex IntelliCore frameless torque motors enable high-precision, high-torque performance across today’s most advanced robotic and automation platforms. From industrial arms and quadruped robots to humanoid systems and smart agricultural vehicles, our direct-drive motor technology delivers the smooth motion, dynamic response, and compact integration required for next-generation intelligent machines.

High-Precision Motion for Industrial Robotic Arms

Our frameless torque motors deliver the smooth, direct-drive performance required for high-accuracy robotic joints and advanced joint actuators. With high torque density, low inertia, and exceptional control resolution, they enable faster response, tighter repeatability, and stable operation in demanding industrial robotics environments. Designed for seamless integration, they support compact mechanical structures while maximizing payload and articulation efficiency.

Agile, Dynamic Motion for AI Robotic Dogs

Our frameless torque motors provide the high torque density, low inertia, and fast dynamic response required for quadruped robots to move with stability and precision. Their compact form factor enables seamless integration into robotic leg joint modules, supporting natural gait patterns, rapid directional changes, and real-time balance control. Designed for demanding AI mobility platforms, they deliver the reliability and responsiveness needed for advanced quadruped locomotion.

Precision Joint Control for AI Humanoid Robots

Our frameless torque motors deliver the smooth, high-resolution motion required for humanoid robots to perform coordinated, human-like movements. With high torque density, low inertia, and exceptional dynamic response, they support stable walking, balanced posture control, and precise articulation across multiple joints. Their compact, lightweight design integrates naturally into humanoid robotic actuators, enabling fluid motion and long-term operational reliability.

Reliable Torque for Smart Agricultural Vehicles

Our frameless torque motors deliver the stable, high-output performance required for next-generation agricultural robots and autonomous farm vehicles. With strong torque density, smooth direct-drive motion, and excellent thermal reliability, they support steering systems, robotic arms, autonomous tool modules, and mobility platforms operating in harsh agricultural environments. Ideal for smart farming systems, these motors enable precise control and dependable operation across modern field applications.

Customize |

Fully Customizable for Advanced Motion Systems

Maintex IntelliCore offers full customization for our Frameless Torque Motor Series to meet the exact mechanical, electrical, and performance requirements of next-generation robotics, automation systems, and high-precision joint modules. From stator winding design to rotor geometry, thermal optimization, and integration-ready mounting structures, our engineering team tailors every parameter to ensure seamless performance inside your actuator, robotic joint, or compact motion system. Whether you’re developing humanoids, collaborative arms, AMRs, or specialized industrial mechanisms, we deliver motor solutions designed around your unique application.

Mechanical Customization

Custom rotor magnet configuration (IPM/SPM variants)

Stator OD/ID adjustments for tight integration

Custom axial height and stack length

Precision hollow-shaft and through-bore options

Custom flange, mounting holes, and integration geometry

Lightweight or high-rigidity structural options

Electrical Customization

Custom windings for torque, speed, Kv/Kt, and current targets

Voltage range optimization (low-voltage robots to high-voltage industrial)

Multi-pole or high-pole count configurations

Back-EMF tuning for high-resolution control

Reduced cogging torque winding options

Encoder-ready configurations & feedback integration support

Performance Customization

Torque constant optimization (Kt tuning)

Continuous/peak torque profile tuning

Thermal path optimization for high-duty cycles

Low-cogging magnetic architecture

Smoothness optimization for precision motion

Dynamic response calibration for robotics & actuation

Environmental & Reliability Enhancements

High-temperature insulation materials

Moisture-resistant varnish and coating options

Reinforced rotor bonding for high-speed stability

Extended life bearings (when used in housed solutions)

Vibration-resistant and shock-resistant design options

From early-stage prototyping to full-scale production, Maintex IntelliCore delivers fully customized frameless torque motor solutions engineered for precision, reliability, and seamless integration inside your advanced motion systems.

Insights |

Engineered Versatility

Frameless torque motors deliver reliable, high-precision motion across a wide range of advanced equipment beyond the primary robotics and mobility platforms. Their compact geometry, high torque density, and smooth direct-drive operation make them suitable for numerous high-performance mechatronic systems.

Other Applications:

Medical and laboratory automation

Semiconductor and inspection systems

UAV, gimbals, and stabilization platforms

Packaging, pick-and-place, and vision equipment

Service robots and autonomous delivery platforms

High-precision motion stages and CNC systems

Key Advantages:

Compact, lightweight design for tight integration

High torque density and excellent efficiency

Low inertia for fast acceleration and dynamic response

Cogging-minimized rotation for smooth, precise control

Direct-drive architecture reduces mechanical backlash

Fully customizable windings, mounting, and interfaces

Insights |

Frameless Torque Motor FAQs

Understanding how frameless torque motors perform, integrate, and compare to other drive technologies is essential for successful system design. This FAQ provides clear technical guidance on selection, customization, thermal management, control systems, and application suitability for robotics, automation, and advanced mechatronic platforms.

A frameless torque motor consists of only the stator and rotor, allowing integrators to embed it directly into their mechanical structure. This eliminates the housing and shaft constraints of traditional motors, enabling compact integration, lower inertia, and higher torque density.

They excel in robotic joints, humanoid robots, quadruped robots, industrial manipulators, gimbals, medical devices, semiconductor tools, and high-precision automation systems where smooth, direct-drive motion is required.

Selection is based on required continuous torque, peak torque, speed, available installation space, inertia matching, and thermal conditions. Our engineering team can assist with sizing based on your application’s mechanical and electrical requirements.

Continuous torque is the load the motor can sustain indefinitely without overheating.

Peak torque is the maximum short-term torque available for dynamic movements like lifting, acceleration, or stabilization.

Yes. We support customization of windings, stator dimensions, mounting holes, rotor geometry, cable routing, connector types, insulation class, and other mechanical or electrical parameters.

Frameless torque motors work with a wide range of encoders, including absolute, incremental, magnetic, optical, and high-resolution encoders commonly used in robotic joints and precision control systems.

Most BLDC or PMSM servo drivers that support three-phase sinusoidal commutation are compatible. We can recommend suitable controllers depending on your speed, torque, and resolution requirements.

Proper thermal paths are essential. This typically involves bonding the stator to the housing and ensuring sufficient conduction to the frame. We can provide thermal guidelines and integration support for optimal performance.

Direct-drive systems eliminate backlash, reduce mechanical wear, increase lifespan, improve control accuracy, and provide smoother, quieter motion—especially important in robotics and precision automation.

Yes, depending on winding and mechanical design, but they are primarily optimized for high-torque, low-to-medium-speed applications. We can customize winding profiles for speed-focused applications if needed.

Yes, with appropriate sealing, housing, and cooling design. We offer specialized coatings and material options for applications requiring moisture, dust, or corrosion resistance.

Absolutely. Our team provides support for motor sizing, CAD models, thermal design, controller selection, encoder pairing, and complete integration guidance for robotic and automation platforms.

Frameless torque motors are ideal when you need direct-drive motion with zero backlash, smooth rotation, and high precision—such as in robotic joints, gimbals, medical devices, and semiconductor equipment. Geared motors are better for applications requiring high torque at very low speeds but with less focus on smoothness or precision. Choose frameless torque motors when accuracy, responsiveness, and long-term reliability are top priorities.

Cost is influenced by motor size, custom winding requirements, quantity, magnet grade, insulation class, thermal specifications, and any mechanical customization such as modified stator or rotor geometry. Higher performance materials and tight tolerances also impact cost. We provide tailored quotations based on performance targets and production volume.