Reliable EC Motor / Fan Solutions for Ventilation Units

High-efficiency airflow for modern agriculture and industry.

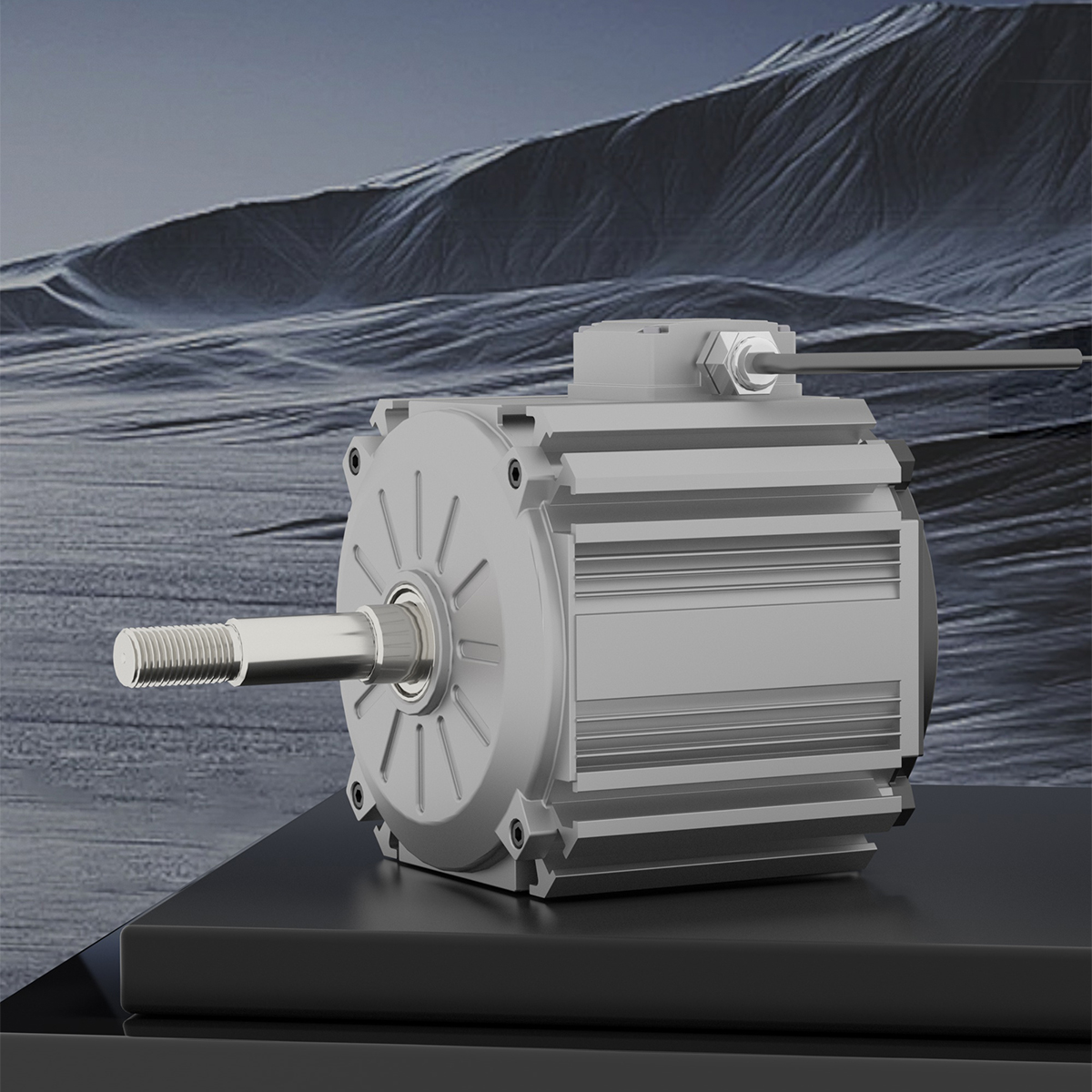

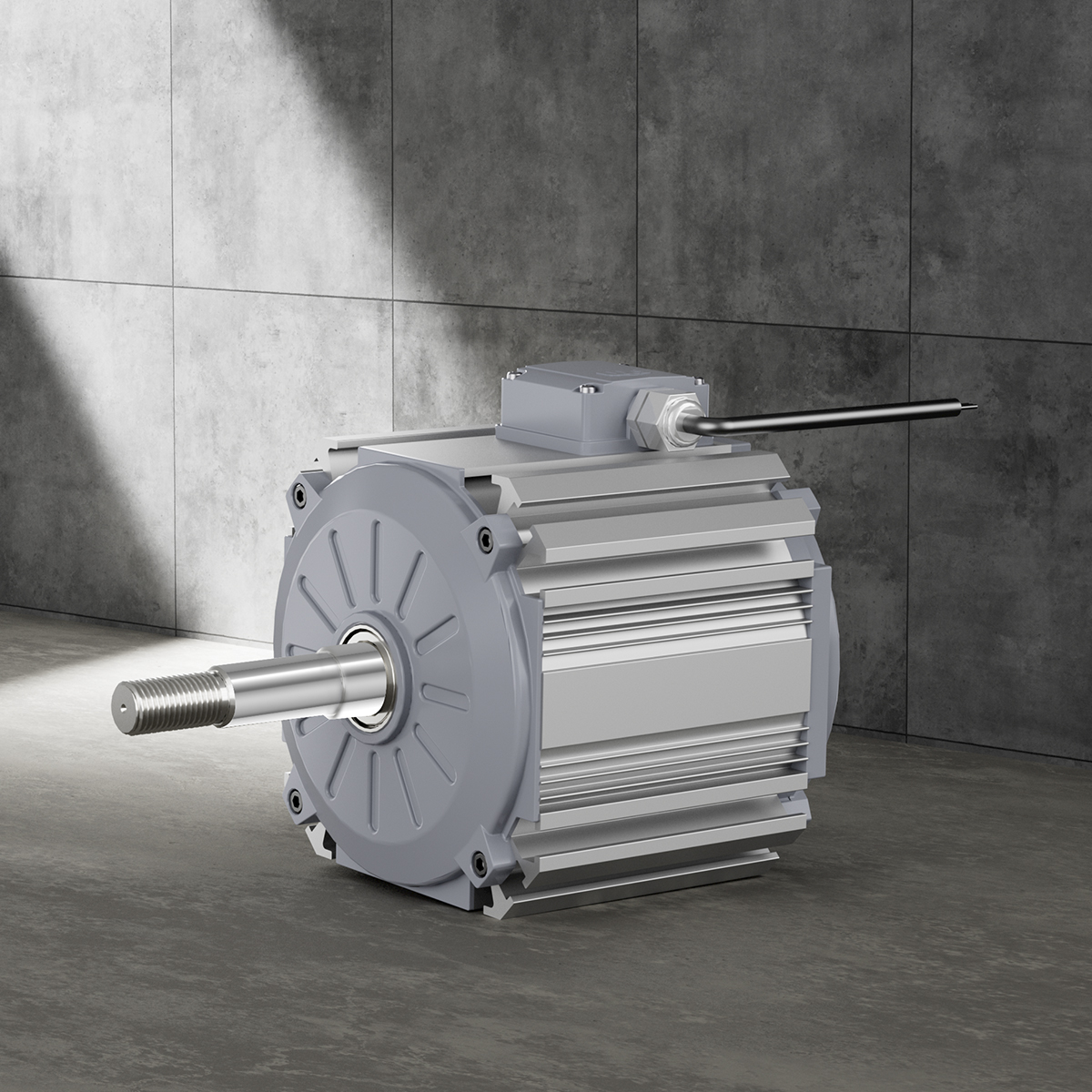

The Maintex IntelliCore EC Fan Series delivers high-efficiency performance for industrial and agricultural ventilation systems, combining strong airflow output with low energy consumption and long-term reliability. Designed for tunnel fans, circulation fans, greenhouse ventilation, livestock barns, and industrial HVAC units, these motors provide stable torque, quiet operation, and precise speed control across harsh environments. With customizable shaft, housing, and control configurations, our EC motors ensure optimal performance for any airflow application.

Airflow |

High-Efficiency EC Motors for Industrial & Agricultural Airflow

Engineered for continuous-duty ventilation, Maintex IntelliCore EC motors deliver powerful airflow, low energy consumption, and long-life reliability for farms, greenhouses, poultry houses, and industrial workshops. Built for demanding environments, our EC motors provide consistent, stable performance in modern agricultural and industrial ventilation systems.

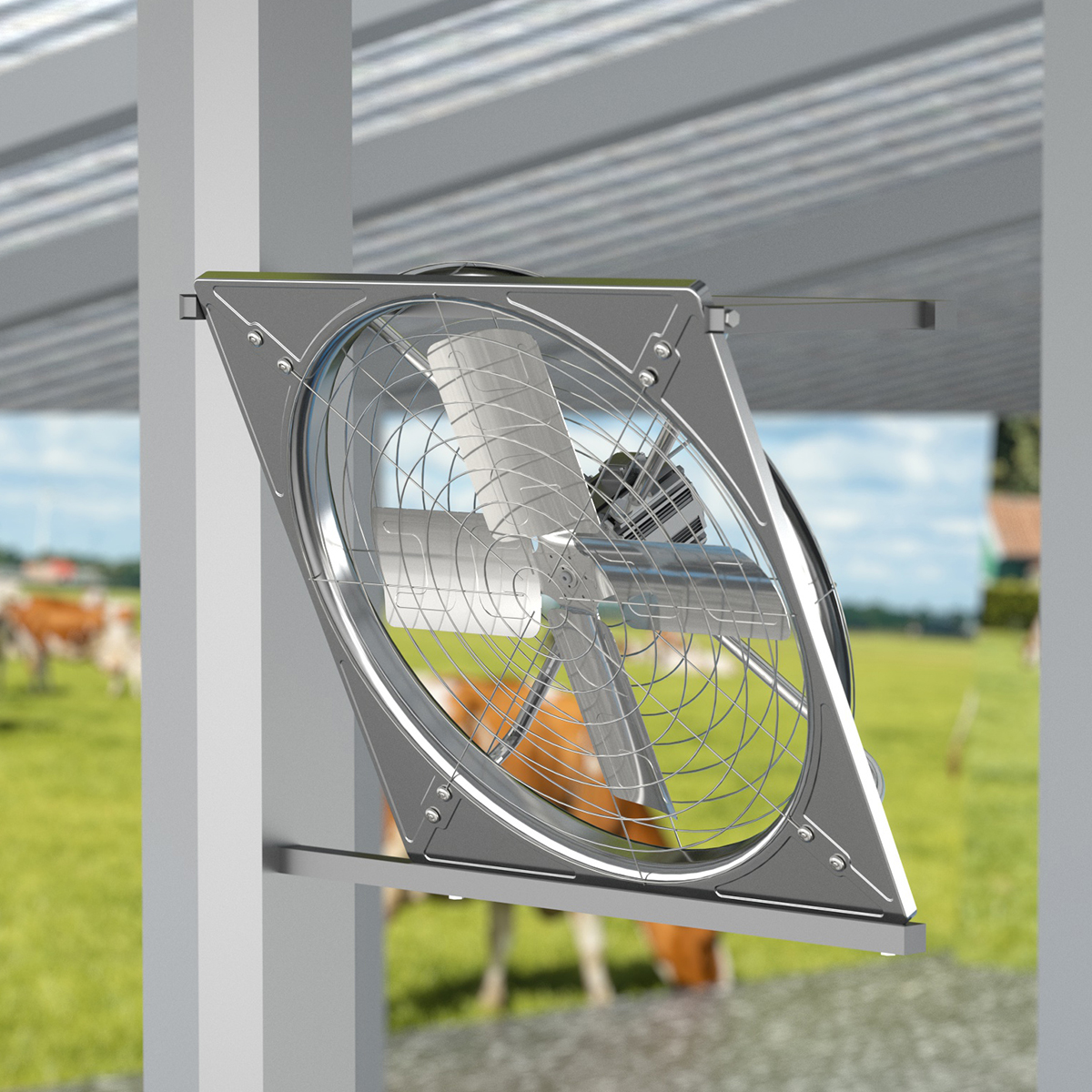

Efficient Ventilation for Modern Farming

Our EC motors deliver powerful, energy-efficient airflow for tunnel fans, barn ventilation, cooling systems, and smart farming environments. Designed for continuous operation in demanding agricultural conditions, they ensure stable performance, long service life, and precise speed control for livestock, greenhouse, and crop-protection applications.

Reliable Ventilation for Livestock & Poultry Environments

Our EC motors provide powerful, energy-efficient airflow for barns, poultry houses, and large-scale livestock facilities. Designed for continuous operation in dusty, humid, and high-ammonia environments, they deliver stable torque, quiet performance, and precise speed control to maintain healthy air quality and consistent climate conditions for animals.

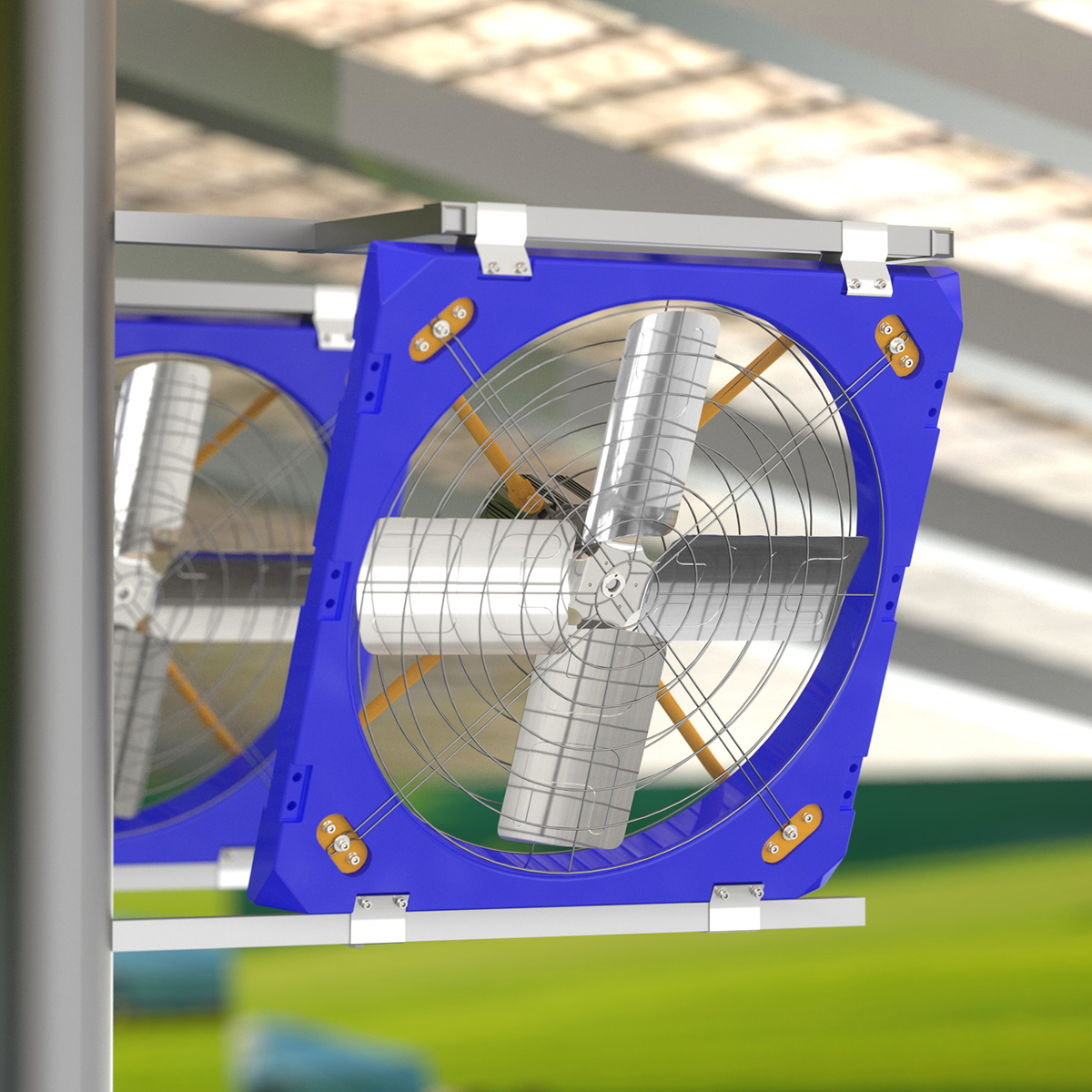

Precise Airflow for Greenhouses & Crop Storage

Our EC motors deliver stable, energy-efficient ventilation for greenhouses, nurseries, and crop storage facilities. Designed for continuous operation in warm, humid environments, they ensure consistent airflow, temperature control, and humidity management to maintain optimal growing conditions and protect stored produce. With precise speed regulation and long service life, they support reliable climate control across all seasons.

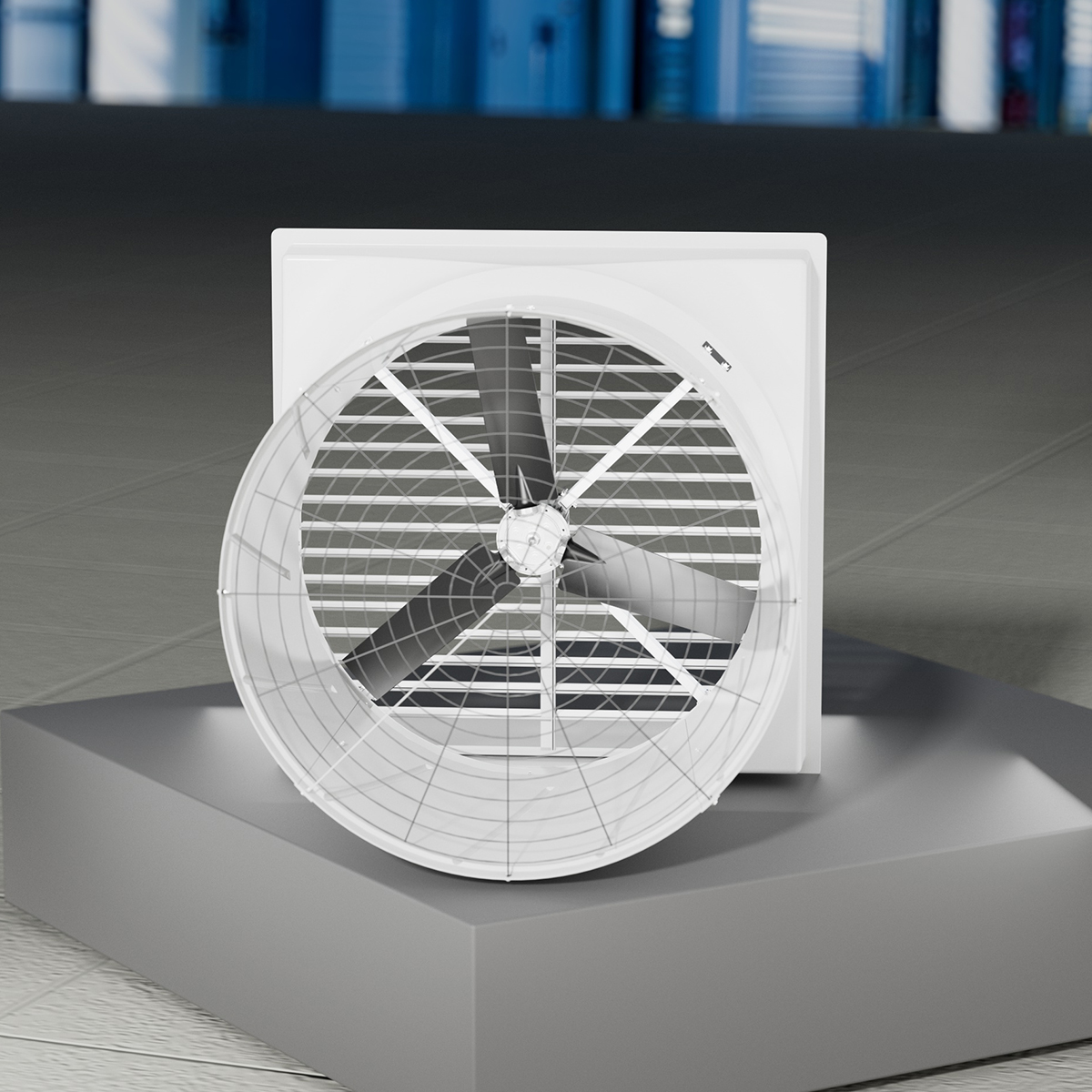

High-Performance Ventilation for Workshops & Warehouses

Our EC motors provide powerful, energy-efficient airflow for industrial workshops, warehouses, and heavy-duty production spaces. Designed for long operating hours and changing load conditions, they deliver stable torque, low noise, and precise speed control. Their durable construction ensures reliable performance in dusty, high-temperature, and high-humidity environments, improving air circulation, worker comfort, and operational safety.

Customize |

Fully Customizable for Industrial & Agricultural Airflow Systems

Maintex IntelliCore offers full customization for our EC Motor Series and industrial fan solutions, ensuring precise airflow performance, energy efficiency, and reliable operation across agricultural, HVAC, and commercial environments. From ventilation fans and greenhouse systems to livestock barns and industrial workshops, our motors and fan assemblies can be tailored to your airflow requirements, mounting standards, and environmental conditions. Whether you need optimized speed control, enhanced durability, or custom housing structures, we deliver solutions built for long-term, continuous-duty performance.

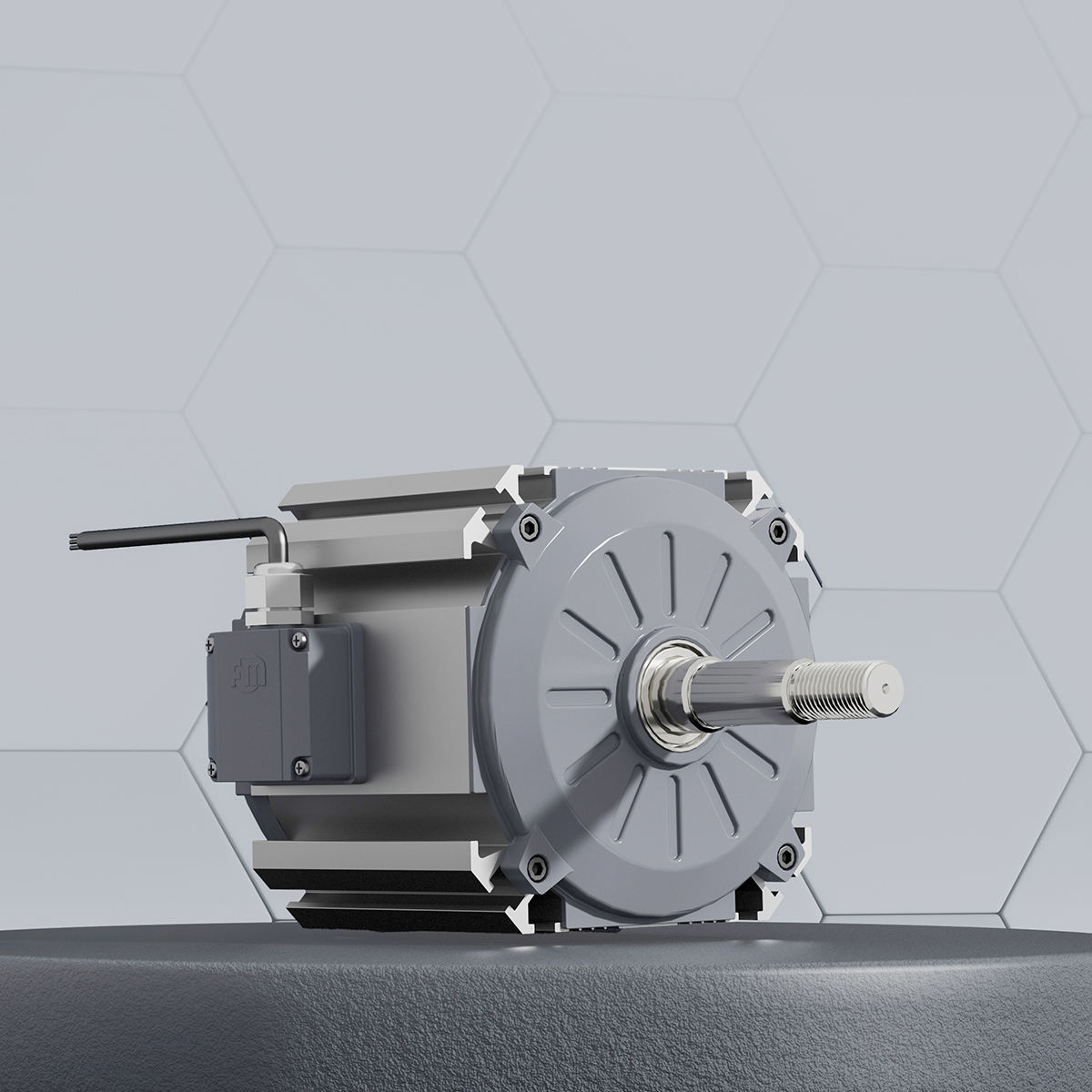

Mechanical Customization

Custom fan blade design (diameter, pitch, blade count)

Housing size, material, and frame structure adjustments

Mounting brackets, flange patterns, and installation geometry

Shaft length, diameter, and key configurations

Inlet/outlet cone design & airflow optimization

Dust-proof, moisture-proof, and corrosion-resistant options

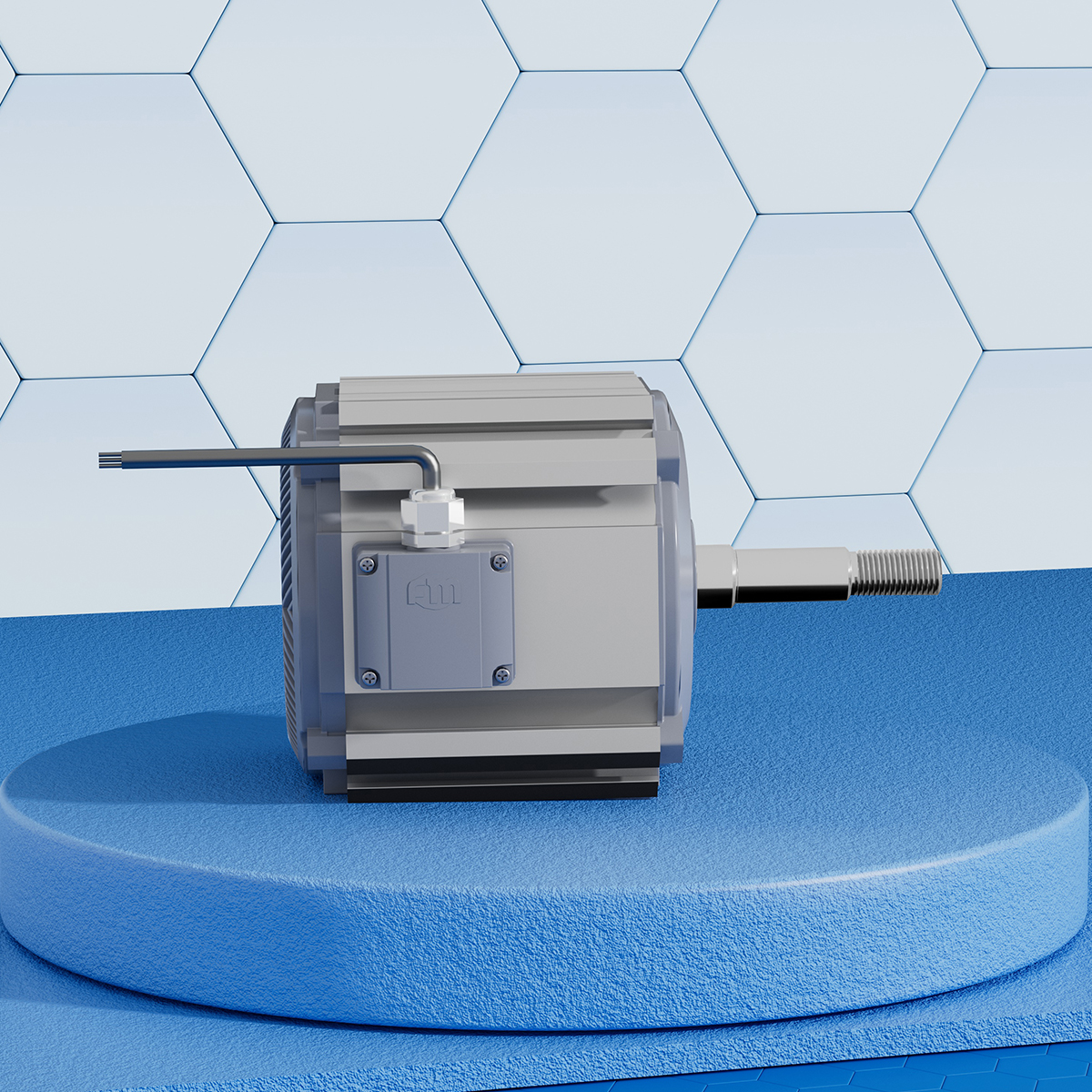

Electrical Customization

Custom motor windings for voltage, torque, and speed targets

Variable speed control options (0–10V, PWM, RS485, Modbus, CAN)

Integrated or external driver design

Wiring length, connector type, and cable routing customization

Efficiency tuning for agricultural or continuous-duty applications

Performance Customization

Airflow performance tuning (CFM optimization)

Static pressure and high-pressure blade configurations

Noise reduction enhancements

High-torque startup tuning for heavy-duty fans

Thermal management optimization for 24/7 operation

Speed curve calibration for ventilation automation systems

Environmental & Reliability Enhancements

High-humidity and corrosive-environment protection

Anti-ammonia coating for livestock barns

Waterproof & dustproof sealing (IP55–IP67 options)

Heavy-duty bearings for long service life

Extended-temperature operation for extreme climates

From greenhouse ventilation to industrial workshops and livestock barns, Maintex IntelliCore provides fully customizable EC motors and fan systems engineered for reliable airflow, low energy consumption, and long-lasting performance in demanding environments.

Versatility |

Versatility in Airflow

Our EC motors are engineered for versatility across a wide range of ventilation systems in agriculture, industry, and commercial environments. With strong airflow output, high efficiency, and durable construction, they provide reliable performance in applications that require long operating hours, precise climate control, and consistent airflow stability. Whether integrated into large-scale farms or industrial facilities, these motors deliver dependable results in diverse, demanding settings.

Other Applications:

Greenhouses and nurseries

Industrial workshops and production lines

Storage warehouses and distribution centers

Poultry, swine, and livestock facilities

HVAC units and commercial ventilation

Air circulation fans, exhaust fans, and duct systems

Cooling and environmental control modules

Key Advantages:

High airflow efficiency with low energy consumption

Stable torque output for long operating hours

Quiet, smooth performance for indoor and agricultural use

Durable construction for dust, humidity, and harsh environments

Precise speed control for optimized climate management

Flexible customization for shaft, housing, and control modules

Insights |

EC Motor FAQ & Technical Guidance

This FAQ covers the most common technical questions about our EC motors for industrial and agricultural ventilation, including efficiency, compatibility, environmental durability, speed control, and customization options. These answers help integrators and engineers better understand how EC motors perform in real-world ventilation systems and how to select the right configuration for their application.

An EC (Electronically Commutated) motor uses brushless DC technology combined with integrated or external electronic control, offering higher efficiency, quieter operation, and more precise speed control than traditional AC induction motors.

EC motors are ideal for agricultural and industrial fans, including tunnel fans, circulation fans, greenhouse ventilation, poultry and livestock barns, warehouse airflow systems, HVAC units, and high-duty cooling applications.

Yes. EC motors typically consume 20–40% less energy due to improved electromagnetic efficiency and intelligent control. This results in lower operating costs, especially in continuous-runtime applications such as barns and industrial workshops.

Yes. Our EC motors are engineered for dust, humidity, high-ammonia environments, and temperature fluctuations. Optional coatings, upgraded insulation, and sealed designs improve durability for barns, poultry houses, and greenhouses.

Yes. We support customization of windings, stator dimensions, mounting holes, rotor geometry, cable routing, connector types, insulation class, and other mechanical or electrical parameters.

Depending on the model, EC motors may include integrated control electronics or require an external driver. We offer both configurations and can recommend the best option based on your fan type and airflow needs.

Absolutely. EC motors support precise speed control through PWM, analog signal, or digital interfaces. This allows optimized airflow management for climate control, energy savings, and animal welfare.

Yes. We offer customizable shaft, mounting, and housing options to ensure compatible replacement for existing AC motors or seamless integration into new fan designs.

Key advantages include higher energy efficiency, stable torque at variable speeds, quiet performance, long service life, and reliable operation in demanding farm environments.

Lifespan is determined by operating temperature, environmental conditions, load profile, and quality of electronic control. Our motors use high-grade bearings, insulation materials, and protection options to maximize service life.

Yes. EC motors are designed for continuous duty with excellent thermal performance and stable torque output, making them ideal for barns, warehouses, greenhouses, and industrial ventilation systems.

Yes. We can customize motor housing, shaft length, connectors, control electronics, speed profiles, and environmental protection features to match specific fan designs or industry requirements.

Lead time varies by model and customization level, typically ranging from 3–6 weeks. We support both prototyping and medium- to large-scale production based on project needs.