Over the past two years, Canada’s automation and robotics sector has been growing at one of the fastest rates in North America. From emerging robotics startups in Waterloo to established integrators across Ontario, BC, Alberta and Québec, manufacturers are under increasing pressure to deliver faster, more reliable, and more compact automation systems.

As supply chains continue to diversify and reshoring gains momentum, many Canadian companies are re-evaluating the core components inside their systems — especially motors. Precision, noise performance, integrated control, and long-term reliability have become critical differentiators.

At Maintex IntelliCore Inc., these shifts are exactly where our work begins.

Why precision motors are becoming mission-critical

Across robotics, medical devices, inspection automation, warehouse AMRs, collaborative arms, and even agricultural systems, we are seeing three clear trends:

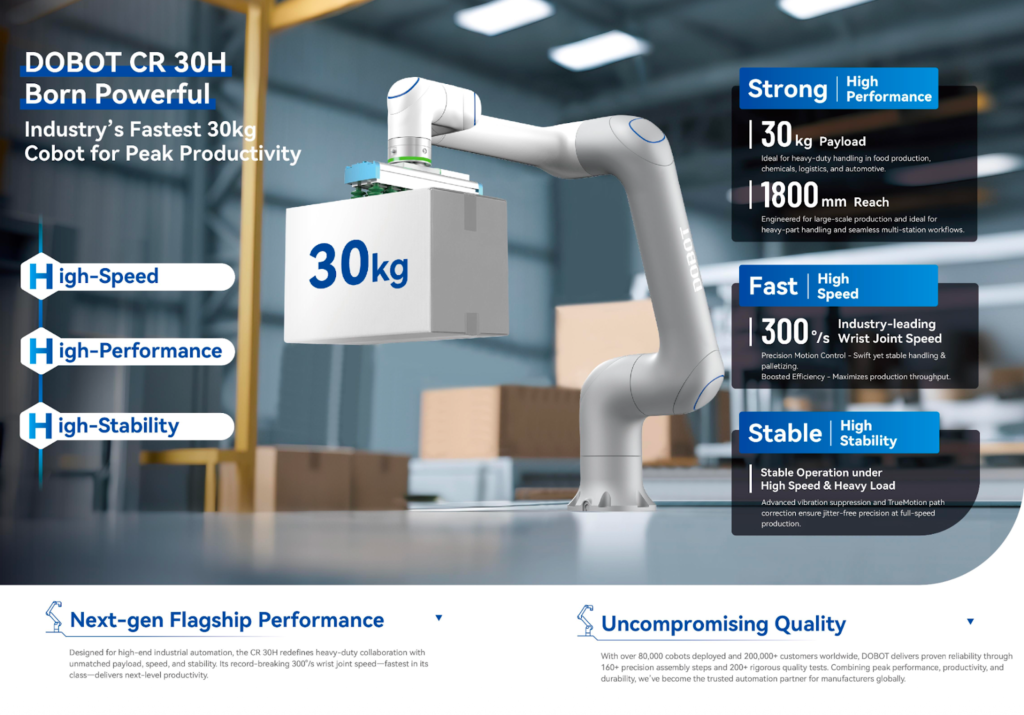

1. Compact high-torque designs are replacing traditional bulky motors

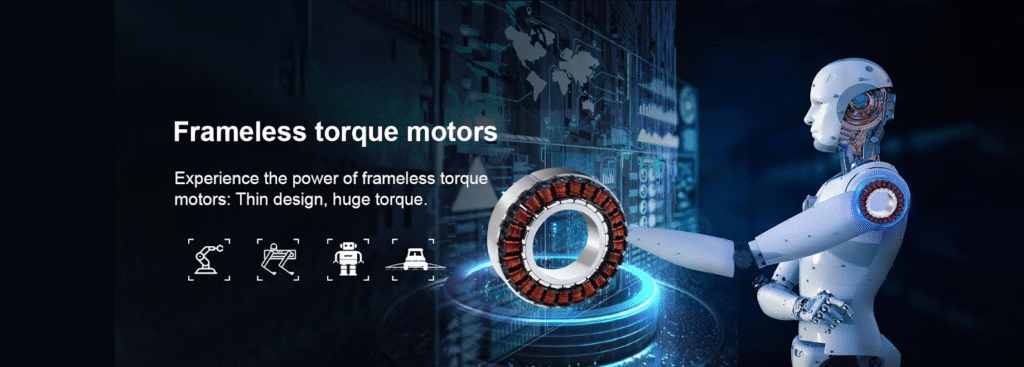

Design teams want higher torque density and lower inertia to reduce mechanical complexity. Frameless torque motors and compact BLDC solutions have become the preferred approach for many next-generation designs.

2. Customization is no longer optional

Canadian integrators are moving away from “catalog-only” models. They need exact mounting structures, cable directions, encoder options, and torque/output profiles. This shift is particularly strong among smaller integrators who build one-off or limited-run automation systems.

3. Reliability and certification are becoming a procurement standard

Many customers are preparing for North American or European market compliance. Certifications such as CE, RoHS, ISO9001/14001, and enhanced QC documentation are increasingly expected during RFQ stages.

How Maintex IntelliCore supports this shift

Our engineering and supply teams work closely with Canadian integrators and manufacturers to provide:

- Custom frameless torque motors (low cogging, high torque density)

- High-precision BLDC motors with integrated drives

- PM / Hybrid stepper motors optimized for gearboxes and reducers

- Joint motors for collaborative arms and automation joints

- Rapid customization programs for prototype + medium-scale production

Whether it’s a robotics startup in early prototyping or a mid-size integrator scaling a new automation platform, our focus remains consistent:

deliver reliable, configurable motion solutions that reduce design constraints and shorten development cycles.

The industry is moving fast and 2025 will move even faster

We’re seeing strong momentum in smart manufacturing, warehouse robotics, autonomous mobile systems, electric grippers, and compact actuators. These categories will continue to expand in 2025 as more companies look for higher precision and cost-efficient solutions.

Our team will continue to work closely with partners across Canada to support their technical development, from early design all the way to production.

If your team is exploring new motor requirements, evaluating custom designs, or simply benchmarking performance, we’re happy to help.